USA Industrials is a Global Diversified Manufacturer of Industrial Materials and Components

Materials

USA Industrials offers custom material development and the most extensive inventory of stock shapes across metals, plastics, and rubber.

Products

USA Industrials stocks 100,000+ items across a broad range of categories, including fasteners, PVF, power transmission, and seals & gaskets.

Capabilities

With diversified manufacturing capabilities, USA Industrials is a one-stop shop for custom made-to-order parts crafted to your precise specifications.

Quality

We are committed to quality assurance and control. USA Industrials is certified to ISO 9001:2015, ISO 13485:2016, and IATF 16949:2016.

Materials

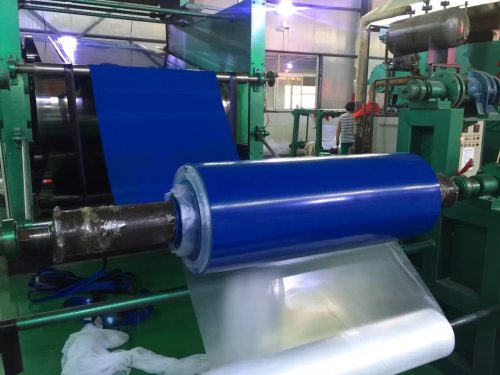

- Metals

- Plastics

- Composites

- Rubber

- Foam/Sponge

Broadest and deepest selection of stock shapes.

Materials that satisfy industry standards, including FDA, NSF, 3A, USP, and UL.

Custom materials and formulations designed to fit your application criteria.

OUR OEM PARTNERS

Spanning across a variety of industries

USA Industrials is trusted by top original equipment and contract manufacturers.

Capabilities

- Molding

- Extrusion

- Machining

- Fabrication

- Post-Processing

Domestic and offshore manufacturing capabilities.

Direct access to our experienced team of material and design engineers.

Reduced development cycle with quotes in days and prototypes in weeks.

Products

- Raw Materials

- Fasteners

- Power Transmission

- Pipe, Valves, & Fittings

- Electrical Components

- Sealing & Gasketing

- Adhesives & Sealants

100,000+ items available from stock.

Diverse collection of industrial products across top MRO categories.

Fully enriched product data designed for seamless integration with e-commerce.